TESTING AND HOMOLOGATION

Thanks to state-of-the-art equipment and technical knowledge of our laboratory, it is possible to perform valildation tests on products. We carry out the necessary checks in compliance with laws and regulations applicable to the specific product.

Every year we invest in the integration of new testing devices, with the aim of broadening its offer of professional services.

Our testing laboratory is run by an experienced and highly qualified staff, able to interact with the designers and to increase the efficiency of the entire development process.

THE TESTS WE CARRY OUT IN OUR LABORATORIES ARE:

PHYSICAL TESTS

Physical assessments include tests on the strength of a device (tensile strength and elongation) and physical performance (force of breaking and breaking strength).

DIMENSIONAL CHECKS

Dimensional checks are essential to assess the conformity of a component (in the prototype phase or in the production phase) to the design specifications, which can be in the form of a 2D technical drawing or 3D file.

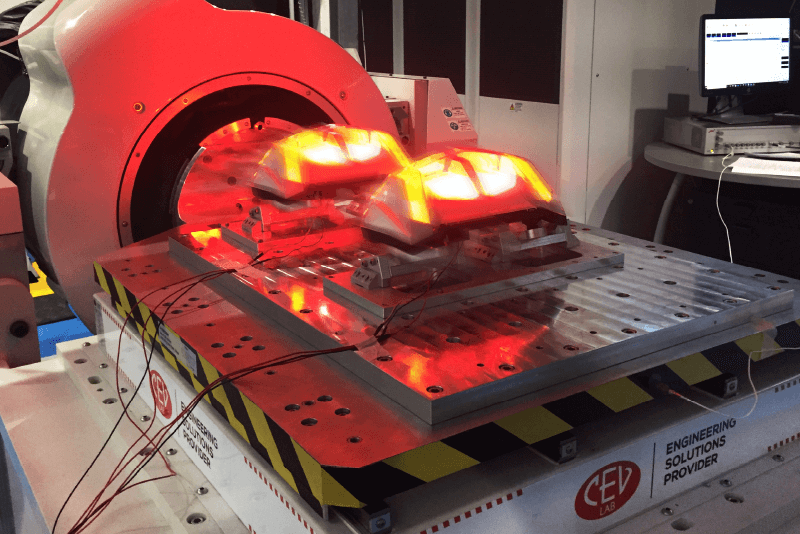

ENVIRONMENTAL TESTS

Heat, cold, humidity, atmospheric agents, extreme environmental conditions can cause damage on the operation of products and equipment. It is essential that your products are able to function perfectly under certain conditions.

ELECTRICAL TESTS

Electrical tests and electromagnetic compatibility tests are used to verify that the equipment is immune to external disturbances and does not produce signals that disturb other nearby equipment.

PHOTOMETRIC TESTS

These tests allow to measure the flux emitted by the luminaires and to detect the photometric distribution of the emission. The laboratories are installed inside dark rooms covered with materials that limit the amplification of noise within the allowed limits.